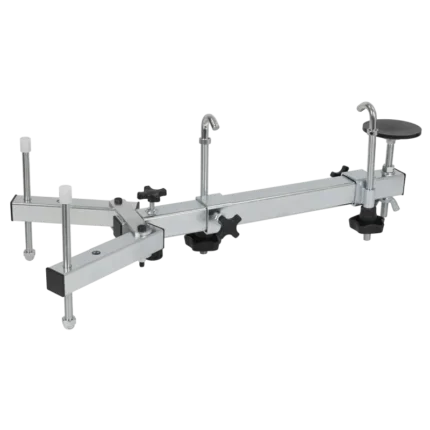

Folding 360º Rotating Engine Stand with Geared Handle Drive 680kg Capacity

Folding 360º Rotating Engine Stand with Geared Handle Drive 680kg Capacity

This heavy-duty engine stand provides professional-grade support for larger engines with its substantial 680kg capacity and precision 360° rotation system. The geared handle drive delivers smooth, controlled positioning of substantial engine assemblies up to 700mm in length, while four fully adjustable mounting arms accommodate diverse bolt patterns across various engine types. Built with safety as a priority, the unit incorporates a positive screw lock mechanism that secures engines at specific angles during maintenance procedures. The robust frame includes support feet and swivel castors for excellent stability and manoeuvrability, while the clever folding design with clevis pins and clips allows compact storage at 1080 x 895 x 890mm. Weighing 50.4kg, this workshop essential combines industrial strength with practical features for efficient engine maintenance on heavier automotive and commercial power plants.

Precision Engine Maintenance Equipment

Heavy-Duty Capacity Rating

The 680kg weight capacity accommodates large displacement automotive engines, commercial vehicle power plants, and complete engine-transmission assemblies, providing sufficient strength for cast iron diesel blocks, heavy equipment engines, and vintage V8s with substantial margin of safety.

Precision Rotation Control

The geared handle drive mechanism converts minimal operator input into controlled 360° engine rotation, enabling single-person positioning of extremely heavy engines without strain, enhancing safety during maintenance procedures on substantial engine assemblies.

Adaptable Mounting Configuration

Four independently adjustable mounting arms with multiple bolt hole positions adapt to virtually any engine bolt pattern, eliminating the need for engine-specific adaptors or mounting plates while ensuring secure attachment to diverse engine designs from different manufacturers.

Enhanced Stability Features

The combination of support feet and four swivel castors creates an exceptionally stable platform even when fully loaded, preventing unwanted movement during torque application while still allowing precise positioning around the workshop when mobility is required.

Positive Locking System

The robust screw lock mechanism securely maintains engines at the exact angle required for specific maintenance tasks, preventing unexpected rotation when applying force to fasteners or removing heavy components, significantly enhancing both work efficiency and technician safety.

Practical Storage Design

Despite its industrial capacity, the stand incorporates a folding mechanism using clevis pins and securing clips that enables compact storage when not in use, addressing workshop space constraints without compromising structural integrity or weight capacity when deployed.

Practical Applications

Commercial Vehicle Maintenance: Safely supports larger diesel engines from trucks, buses, and agricultural equipment during major overhauls, providing the stability required for heavy component removal and the rotation capability to access all areas of these substantial engine blocks without repositioning or multiple lifting operations.

Complete Powertrain Service: Accommodates combined engine-transmission assemblies from larger vehicles, holding the entire powertrain securely during clutch replacement, bellhousing service, or engine-to-transmission alignment procedures that require access to the interface between these major components.

Vintage Engine Restoration: Provides the capacity needed for handling heavier cast iron vintage engines during restoration projects, supporting substantial V8 blocks and associated components while allowing precise positioning for detailed cleaning, machining preparation, and assembly procedures requiring meticulous alignment.