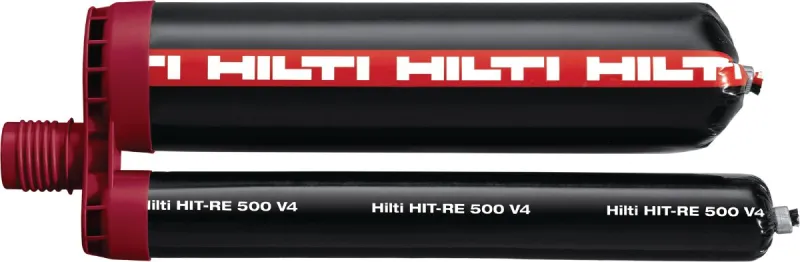

HILTI HIT-RE 300ml 500ml 1400ml V4 Epoxy anchor Injectable mortar HIT-RE min order 10pcs

HILTI HIT-RE 300ml 500ml 1400ml V4 Epoxy anchor Injectable mortar HIT-RE

Injectable mortar HIT-RE

Technical data

Approvals/test reports

BZS/shock, ETA, Fire, Seismic

Seismic loading

Yes

Fatigue loading

Yes

Fire resistance

Yes

PROFIS software

Yes

Clean-Tec

No

Storage and transportation temperature range

5 – 25 °C

Shelf life from date of manufacture (at 23°C and 50% relative humidity)

12 months

Features

- Ultimate performance and model code-compliant design for virtually any concrete-to-concrete and steel-to-concrete connections – ETA assessment for anchoring inc. C1 and C2 seismic and ETA for rebar inc. fire and seismic

- The first epoxy mortar qualified according to EAD 332402-00-0601 for concrete-to-concrete connections – rigid connections can now be designed and executed with post-installed rebars without splices according to the newest design method TR069

- Suitable for the toughest jobsite conditions – works even in diamond-cored, wet or underwater holes, extremely deep injections, large diameters and at temperatures down to -5°C / 23°F

- Improved bond strength in the most demanding applications – such as cracked concrete and seismic C2 conditions

- Easier to specify and order – use PROFIS Engineering to design baseplate connections and PROFIS Rebar to design concrete-to-concrete connections according to EC2, TR069 or the Hilti Design Method

Applications

- Structural connections with post-installed rebar (e.g. slab extensions, wall/column connections, stairs, foundations, etc.)

- Structural renovation of buildings, bridges and other civil works, retrofitting and re-strengthening of concrete members

- Anchoring structural steel connections (e.g. steel columns, beams, etc.)

- Fastening structural baseplates, including in cracked concrete and challenging seismic conditions

- Fastening in natural stone and wood, including GLT and CLT made from spruce, pine or fir